The Volgodonsk-based branch of the Russian company AEM Technologies (part of Atomenergomash, the mechanical engineering division of the Russian nuclear industry corporation Rosatom) has finished welding the upper half of the reactor vessel that will become part of the second power-generating unit of the Belarusian nuclear power plant, the Atomenergomash press service told BelTA.

Before the welding operation the components of the hemisphere had to be assembled with utmost precision. All the parts had to be positioned relatively to each other, with the maximum deviation of only 0.5mm. The automatic welding operation took 15 days, with the welding area constantly heated. After the welding operation the product was left inside a furnace where it was heated to 300C in order to secure the necessary mechanical properties of the metal. The welding seams have to be examined now. After that the inside surface of the hemisphere will be covered with corrosion-resistant alloys.

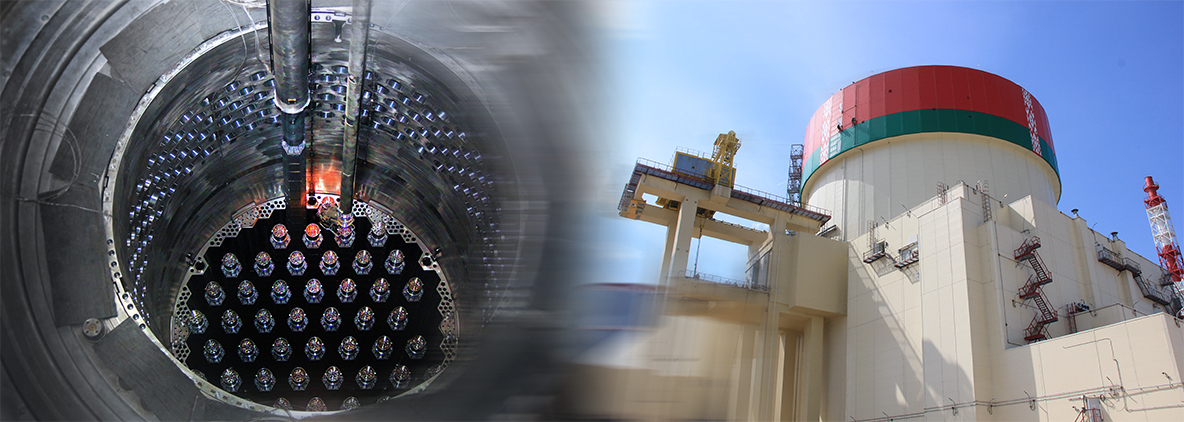

The reactor is a vertical cylinder with an elliptical bottom. The reactor core and the internal components will be located inside.

BelTA reported earlier that the reactor vessel for the first power-generating unit is supposed to be delivered to the construction site of the Belarusian nuclear power plant by the end of the year.